Oil sealed rotary vane vacuum pump working principle

A rotary vane vacuum pump (referred to as a rotary vane pump) is an

oil-sealed mechanical vacuum pump. Its working pressure range is 101325~1.33×10-2 (Pa), which belongs to the low vacuum pump. It can be used alone or as a backing pump for other high vacuum pumps or ultra-high vacuum pumps. It has been widely used in production and scientific research departments such as metallurgy, machinery, military industry, electronics, chemical industry, light industry, petroleum, and medicine.

The rotary vane pump can pump out the dry gas in the sealed container, and if it is equipped with a gas ballast device, it can also pump out a certain amount of condensable gas. But it is not suitable for pumping gas with high oxygen content, corrosive to metal, and chemical reactions to pump oil and dust particles.

The rotary vane pump is one of the most basic vacuum-obtaining equipment in vacuum technology. Rotary vane pumps are mostly small and medium-sized pumps. There are two types of rotary vane pumps: single-stage and two-stage. The so-called two-stage is to connect two single-stage pumps in a series structure. Generally, it is made into two stages to obtain a higher vacuum degree. The relationship between the pumping speed and the inlet pressure of the rotary vane pump is stipulated as follows: when the inlet pressure is 1333Pa, 1.33Pa, and 1.33×10-1 (Pa), the pumping speed value shall not be lower than 95%, 50% and 20%of the nominal pumping speed of the pump.

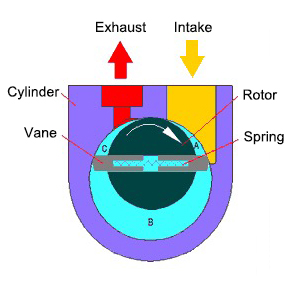

![]()

The rotary vane pump is mainly composed of the pump body, rotor, rotary vane, end cover, spring, and so on. A rotor is eccentrically installed in the cavity of the rotary vane pump, the outer circle of the rotor is tangent to the inner surface of the pump cavity (there is a small gap between the two), and two rotary vanes with springs are installed in the rotor slot. When rotating, relying on the centrifugal force and the tension of the spring to keep the top of the rotary vane in contact with the inner wall of the pump chamber, the rotation of the rotor drives the rotary vane to slide along the inner wall of the pump chamber.The two rotating vanes divide the crescent-shaped space surrounded by the rotor, the pump chamber, and the two end covers into three parts A, B, and C, as shown in the figure. When the rotor rotates in the direction of the arrow, the volume of space A communicating with the suction port increases gradually, and it is in the process of suction. The volume of space C communicating with the exhaust port is gradually reduced, just in the process of exhausting. The volume of space B in the middle is also gradually decreasing, which is in the process of compression. Since the volume of space A gradually increases (that is, expands), the gas pressure decreases, and the external gas pressure at the inlet of the pump is higher than the pressure in space A, so the gas is inhaled.When space A is isolated from the suction port, it turns to the position of space B, the gas starts to be compressed, the volume gradually decreases, and finally communicates with the exhaust port. When the compressed gas exceeds the exhaust pressure, the exhaust valve is pushed open by the compressed gas, and the gas passes through the oil layer in the tank and is discharged into the atmosphere. The purpose of continuous pumping is achieved by the continuous operation of the pump.

One-stage rotary vane vacuum pump working principle

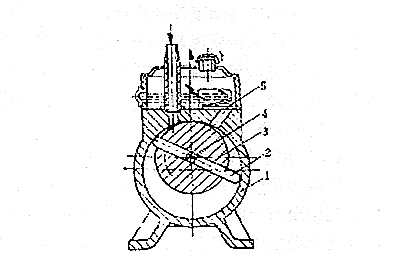

The single-stage rotary vane pump has only one working chamber, and the pump is mainly composed of a stator, a rotary vane, and a rotor. The rotor is installed eccentrically in the pump chamber, and two rotating vanes are installed in the rotor groove, which is close to the cylinder wall due to the elastic force of the spring (there is also a centrifugal force of the rotating vanes after rotation). The rotor and vanes divide the stator cavity into suction and discharge.

When the rotor rotates in the stator cavity, the volume on the side of the air inlet is gradually expanded periodically to inhale the gas, while the volume on the side of the exhaust port is gradually reduced to compress the inhaled gas and discharge it from the exhaust valve.

The vent valve is immersed in oil to prevent atmospheric air from entering the pump. The vacuum pump oil enters the pump chamber through the oil hole and the exhaust valve so that all the moving surfaces in the pump chamber are covered with oil, forming a seal between the suction chamber and the exhaust chamber.

Two stage rotary vane vacuum pump working principle

In order to improve the ultimate vacuum of the pump, in addition to improving the machining accuracy of the pump body, rotor, and rotary vane, and minimizing the assembly gap and harmful space, the most effective way is to connect two single-stage pumps in series to form a two-stage pump.

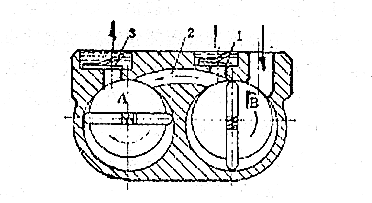

The

two stage rotary vane vacuum pump consists of two working chambers. The two chambers are connected in series and rotate in the same direction at the same speed. A chamber is the front stage of B chamber. A is the low vacuum stage and B is the high vacuum stage. The pumped gas enters the front stage through the high vacuum stage (B ), and is discharged out of the pump through the exhaust valve. The front stage (A) is the same as the single-stage pump, oil enters the pump chamber at any time, while the high vacuum stage (B) only has a small amount of oil when it starts to work, and no oil enters the pump chamber after working for a period of time. When the pump starts to work and the pressure of the inhaled gas is relatively high (such as starting to pump air from atmospheric pressure), the gas is compressed through the B chamber, and the pressure increases sharply, and a part of the compressed gas is directly discharged from the auxiliary exhaust valve (1), and the other part is discharged through the front stage.

When the pump works for a period of time, when the pressure of the gas inhaled by the B chamber is low, even though it is compressed by the B chamber, the pressure cannot reach above one atmospheric pressure, and the auxiliary exhaust valve 1 cannot be discharged, and all the inhaled gas will enter The front-stage A room is discharged through the exhaust valve 3 through the continuous compression of the A room.

After the pump works for a period of time since the pressure of the high-vacuum stage air intake is greatly reduced, the outlet pressure is also very small, so the pressure difference between the inlet and outlet of the B chamber is also small, and the amount of compressed gas returned is correspondingly reduced; at the same time, the latter stage The oil molecules that are easy to evaporate in the pump are continuously sucked away by the front-stage A chamber, and the partial pressure of the oil vapor is reduced. Therefore, the oil pollution of the two-stage pump is smaller than that of the single-stage pump, and the ultimate vacuum degree will be greatly improved.

1 Stage vs. 2 Stage Rotary Vane Vacuum Pump

1 stage rotary vane pump consists of a single rotor with multiple vanes that rotate within a cylindrical chamber. As the rotor spins, centrifugal force pushes the vanes against the chamber wall, creating a seal and forming variable-volume chambers. The pumping action occurs through the expansion and compression of gas in these chambers, resulting in the generation of a vacuum.

Simplicity: 1-stage pumps have a straightforward design with fewer moving parts, making them compact, lightweight, and easy to operate and maintain.

Cost-Effective: These pumps are typically more affordable compared to 2-stage pumps, making them a cost-effective option for applications that do not require extremely low vacuum levels.

Suitable for Low to Medium Vacuum: 1-stage pumps are ideal for applications that require vacuum levels within the range of approximately 100 to 1,000 mbar (millibar).

Efficient for Low Gas Loads: They perform well when handling low gas loads, making them suitable for applications where gas flow rates are not excessive.

In a

2 stage rotary vane pump, the pumping process is divided into two sequential stages, each with its own set of vanes. The first stage, known as the high-vacuum stage, operates similarly to a 1 stage pump, creating an initial level of vacuum. The gas discharged from the first stage then flows into the second stage, where further compression occurs, resulting in even lower vacuum levels.

Higher Vacuum Levels: 2 stage pumps are capable of achieving significantly higher vacuum levels compared to 1 stage pumps. They can reach vacuum levels as low as 0.1 mbar or even lower.

Improved Gas Handling: These pumps are effective in handling higher gas loads and can efficiently evacuate larger volumes of gas.

Enhanced Backstreaming Resistance: The two-stage configuration provides better resistance to backstreaming, preventing oil or contaminants from reaching the vacuum chamber or system.

Suitable for High Vacuum Applications: 2 stage pumps are well-suited for applications requiring high vacuum levels, such as analytical instruments, vacuum coating, and semiconductor manufacturing.

Dernière modification le mardi 26 Septembre 2023 à 08:23:03